Our story

OUR PHILOSOPHY

Organisation

With 30 years of experience in fire and rescue, SCORPE aims to develop ranges of tools that facilitate the work of rescue, police, military teams around the world.

Scorpe people travel the entire world and get the feedback from teams worldwide which allow the company to develop and respond quickly to the demands of the market.

Always offer innovative products, thanks to the experience of its employees and customers.

Over the last 10 years SCORPE has developed over 100 products, building on to the latest available technologies.The strength of our company comes from its collaborators and their group spirit.Be serious without taking yourself seriously.

Our products are not born by chance:

1. Research of needs in the field via the Training Center Sucrerie

At Scorpe, we are constantly seeking solutions to address the emerging needs in rescue equipment for individuals. Thanks to our dedicated training center, the TCS, and in collaboration with our partners, we innovate and adapt our offerings to better serve our clients.

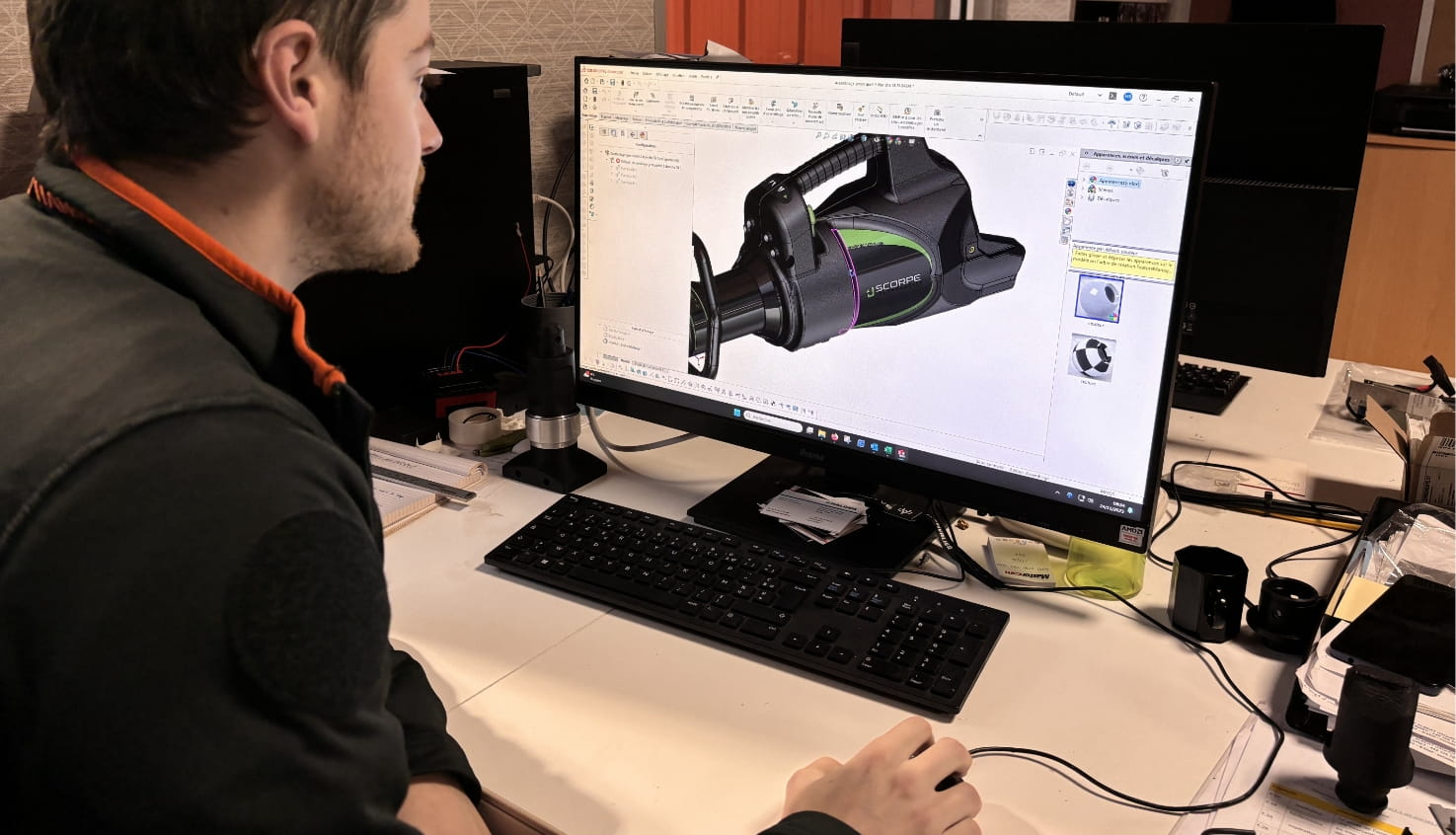

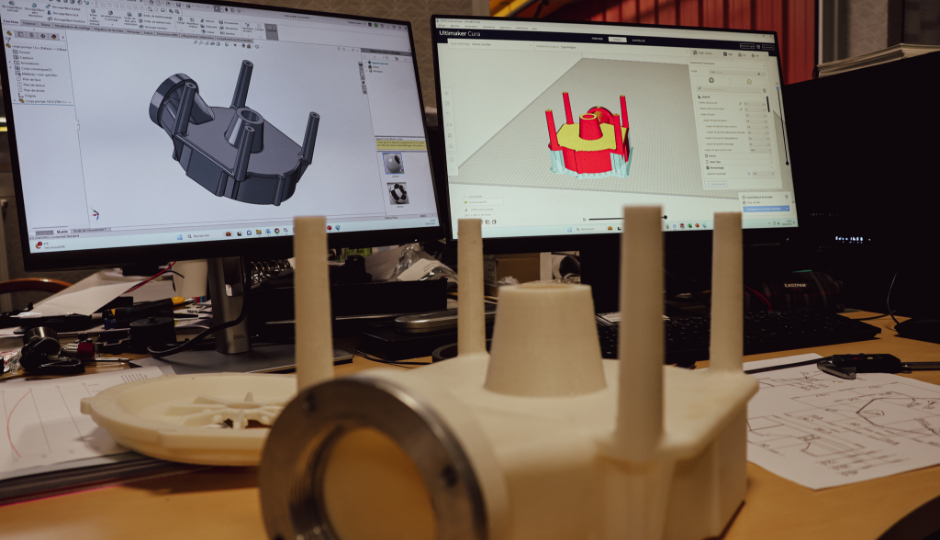

2. Realization of plans via our Innov St Ger design office

Once specific needs are identified, we draft plans for bespoke tools to address these new challenges. All of this is made possible thanks to our research and development department, Innov St Ger.

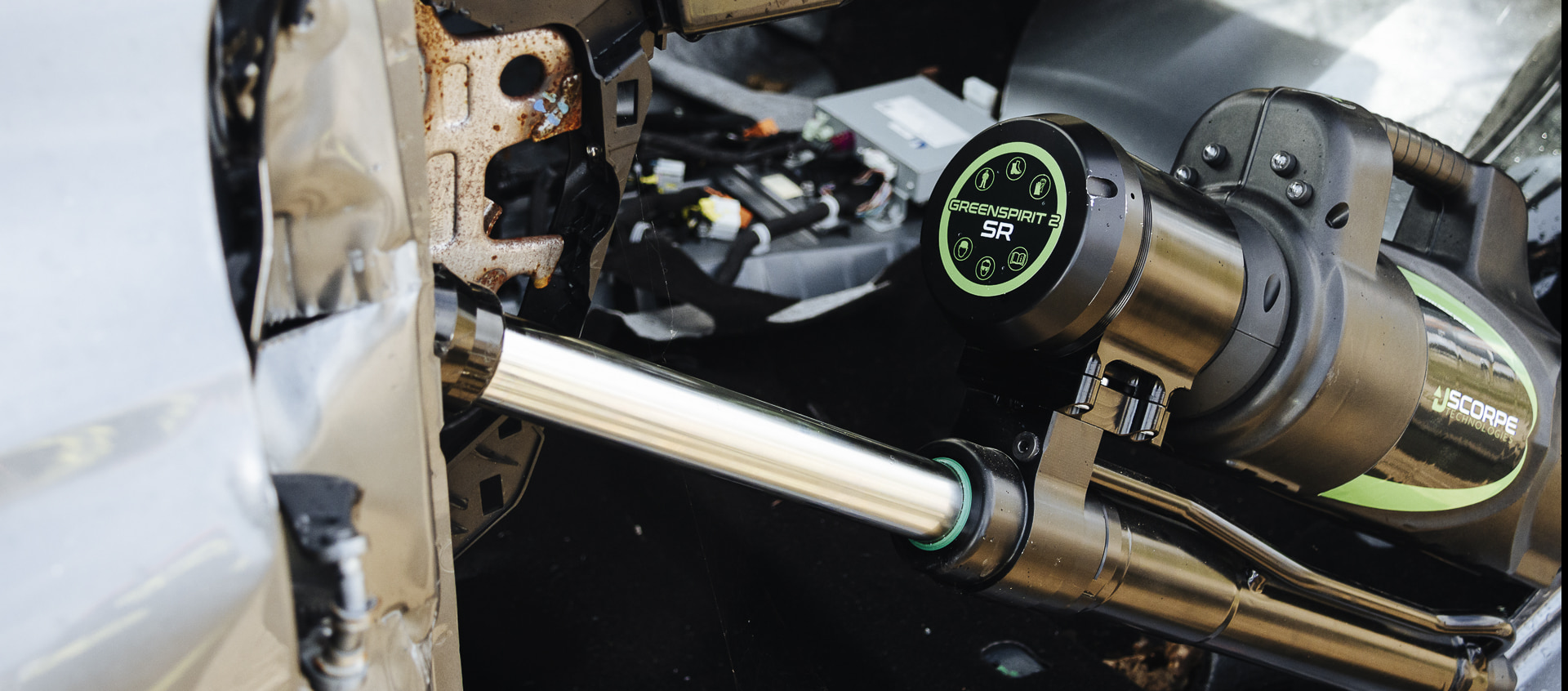

3. Parts manufactured by Sud Arden’ Usinage

Once the plans are finalized, our machining workshop, Sud Arden’, located at the heart of our facilities, takes over to materialize and manufacture these new tools.

4. Assembly of products in-house in our Scorpe Technologies workshops

The assembly of these new tools is carried out in-house, directly within our workshops, ensuring complete control over the manufacturing process and optimal quality.

5. Prototype testing via the Training Center Sucrerie and its professional firefighter expert trainers

The prototypes are put to the test at the Sucrerie Training Center, where our expert trainers, all professional firefighters, assess their performance and effectiveness. This process ensures that each tool meets the highest standards and field requirements.

6. Validation of prototypes by Scorpe Technologies

Each new prototype undergoes a rigorous validation process. This crucial step ensures that all our products meet the strictest standards before they are introduced to the market.

7. Serial production at Scorpe Technologies

Once the prototypes are validated, Scorpe takes over the production directly within its workshops. This internal process allows us to guarantee the quality and efficiency of every product we produce.

8. Technicals and sales support produced by Colibry’s communications agency

Finally, in the last essential step, the Colibry’s communication agency takes charge of creating technical materials and commercial sheets. They are also responsible for all the communication surrounding these new products, ensuring an effective presentation and dissemination to our partners and clients.

OUR FACILITIES

Our offices

Factory

Manufacturing

Testing

Outdoor training and testing area